How PrintShop Works

Why Create Merch?

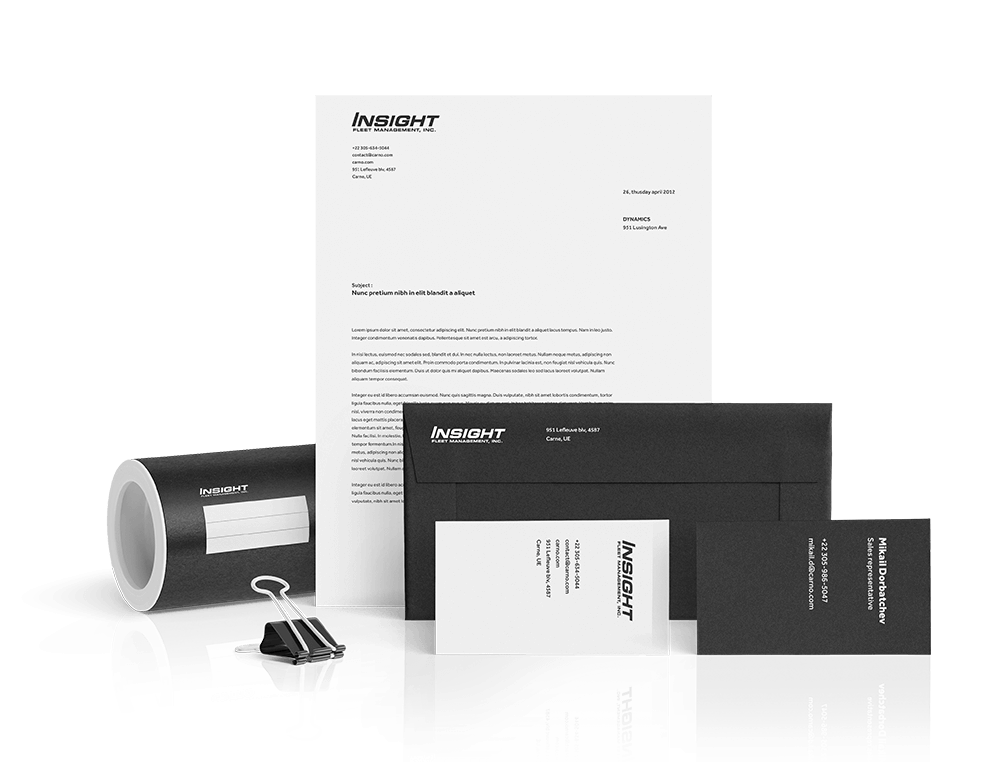

PrintShop by Designhill offers you a platform to bring your creativity to life. It’s like a blank canvas, symbolizing a new start and giving you the opportunity to showcase your artistic side. Customize a range of products with your favorite design, artwork, tagline, or just about anything and sell it to your fans.

If you want to grow your fan base and promote yourself as a brand, creating custom merch is the solution. Merchandising is a great marketing tool that will help in spreading the awareness about your niche and expanding your reach beyond your existing fan base.

Launching your official merch for your fans is a new and fun way to connect with them. They are already following you and by purchasing your merch, they will start loving you even more. So, create your custom products and let your fans flaunt your name.

Do you know of anyone who doesn’t like to have an added source of income? Well, in today’s time nearly everyone wants to earn some extra cash, especially when there is no risk involved.

Whether you are an influencer, NGO, a gamer, musician or anyone with a fan following, launching your merch store with PrintShop comes for free. Plus, you can set your own prices and decide on your profit margins, taking control of your earnings.

Why Open a PrintShop?

Making Money with PrintShop

Our pricing system gives you the flexibility to set your own prices and determine your profit margins. Right from the first sale, you start making money.

Premium Design Service

For shop owners with no experience in design, we have got a special package offering Premium Design Services. By opting for it, they can get access to our pool of designers who will customize the designs as per the requirement and enhance them using their skills.

Product Selection

One thing that makes merch stores a success and their customers happy is its product range. To give your audience a splendid shopping experience, we offer a wide assortment of products that you can choose to sell in your stores. From men, women, and kids’ clothing to accessories and home décor products, we have it all. Not just this, but also we make sure whoever buys from your store gets maximum satisfaction. Hence, the quality of products is our primary focus when printing and delivering. We use the best of materials and premium fabrics to bring that ‘Wow’ factor in your product. When it comes to style and fit, we ensure to follow the latest trends so your fans look fashionable.

Industry-Leading Technology to Create Awesome Products

We use the best technology for manufacturing quality products.

- DTG Printing: DTG or Direct to Garment printing makes use of DTG inks and Kornit series printer. We use this technique for printing t-shirts, tank tops, crop tops, hoodies, sweatshirts, and tote bags.

- Embroidery: On select t-shirts, we use embroidery to bring out the finest details of the design.

- Digitization and Embroidery: In case of hats, we first digitize- convert the graphics into a stitch file which is then processed by the embroidery machine. There are three different techniques used in hat embroidery- Flat Embroidery; 3D puff for a raised look; and Partial 3D puff for a combination of both flat and raised look.

- Sublimation Inks: For designing mugs, graphics are printed using sublimation inks on sublimation paper. This paper is then wrapped around the mug and kept in an oven for transferring the design on to the mug.

- UV Printing Technique: Under this technology, UV-curable ink is used to print the graphics on the phone case. When UV light comes in contact with the case, the ink gets cured, forming a hard coating.

- Sublimation Paper and Specialty Inks: Like mugs, socks too are printed using sublimation paper and special inks. Graphics are printed on the paper which is then wrapped around the socks. After the heating process, the ink gets converted into gas and absorbed in the fabric. This technology is also used for printing all-over print tote bags and towels.

- Sublimation, Hand-Cut and Sewn: Pillow cases undergo the sublimation process wherein the graphics are transferred on sublimation paper using specialty inks. The fabric is then placed inside the printed paper and put through a heat process that transfers the ink on the fabric. After printing is done, the fabric is cut into the shape of a pillow and sewn to make the finished product.

- Fixed price packages

- Hand crafted designs from World-class designers

- Dozens of concepts to pick from

- 100% money back guarantee

- Work with a single designer

- Hand crafted designs from World-class designers

- Options within all price ranges

- Flexible turnaround time